THOR44

Metal Powders

Our metal powders are gas-atomized through our patent-pending Spray Forming process. The powders are sieved to custom sizes and have been qualified for Additive Manufacturing processes including Laser Powder Bed Fusion, Binder Jetting and Laser Cladding. Spray-formed powders are characterized by:

- Unmatched low CO2 footprint

- Spherical shape with few satellites

- Excellent flowability

- Low internal gas porosity

- Chemical compatibility with corresponding spray-formed steel

Learn more about our Spray Forming process here.

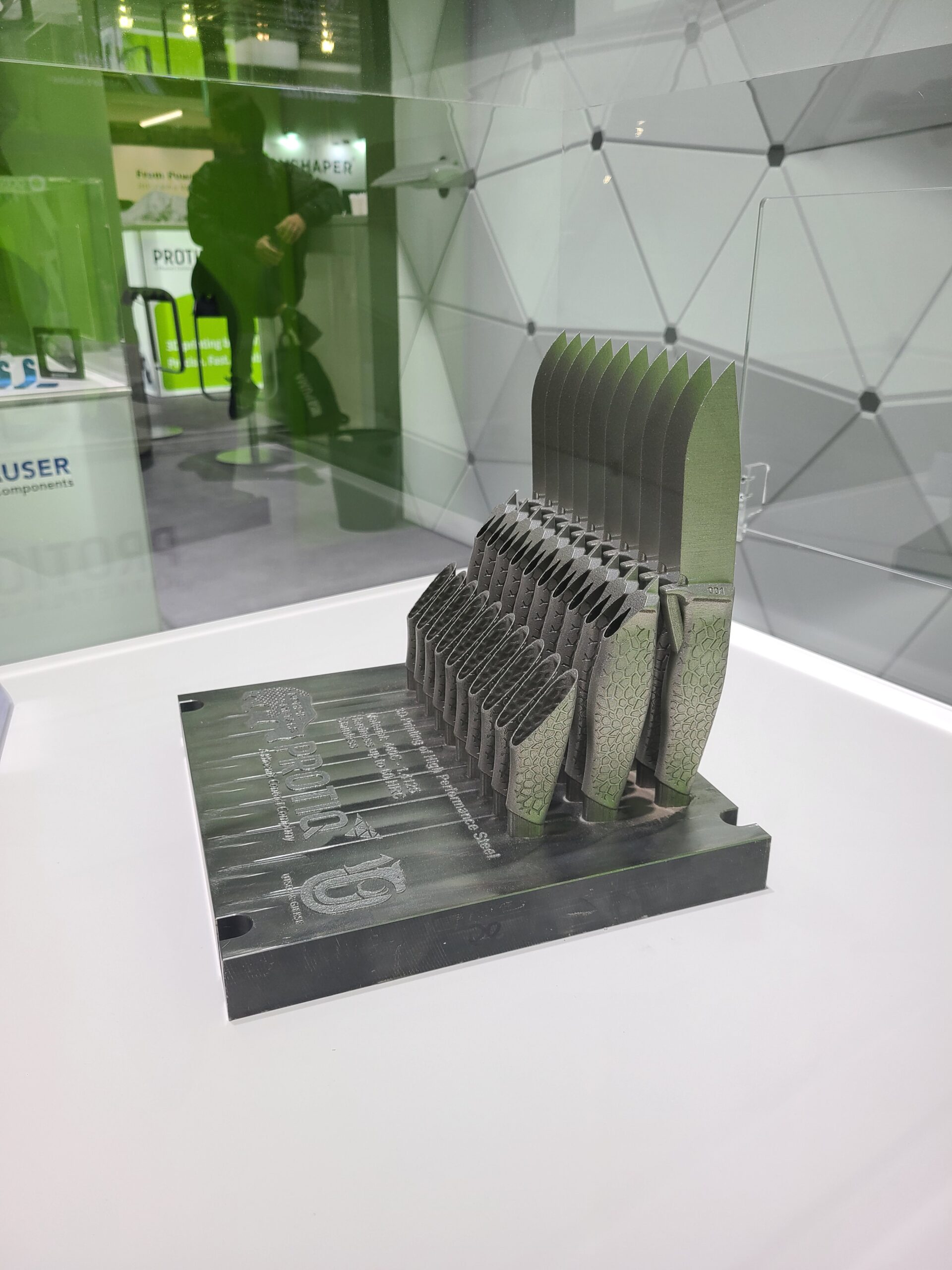

THOR44 knives printed on a commercial EOSM290 Laser Powder Bed Fusion system without high-temperature preheating at Protiq. Displayed at formnext 2023, the world’s largest 3D printing fair.

THOR44 Metal Powder

Technical specifications:

440C | 1.4125 | X105CrMoV17 | S44004

THOR44 is a high-carbon martensitic stainless steel for Laser Powder Bed Fusion (LPBF). THOR44 exhibits high manufacturability and can be tailored by dedicated heat treatments to adapt final properties such as hardness and wear resistance to your application. Our Additive Manufacturing and heat treatment experts are glad to assist you with recommendations.

With an achievable hardness of up to 65 HRC, THOR44 is the hardest available tool steel on the LPBF market. Due to its exceptional wear resistance, it can be used in a variety of applications including:

- Rolling, ball, and roller bearings

- Valve parts

- Gears

- Dies and injection molds

- Food processing tools

- Knife blades

- Surgical instruments

Benefits:

- Hardest available tool steel on the LPBF market

- Easy to print

- High corrosion resistance

- ~50% higher thermal conductivity compared to M300

- No cobalt and nickel

ODIN44

ODIN44Tool SteelOur spray-formed tool steel is available as rounds, bars, flat steel, sheets or precision machined in custom dimensions according to your needs. Spray FormingDue to our patent-pending Spray Forming process, our steel exhibits premium qualities:...

THOR15

THOR15Metal PowdersOur metal powders are gas-atomized through our patent-pending Spray Forming process. The powders are sieved to custom sizes and have been qualified for Additive Manufacturing processes including Laser Powder Bed Fusion, Binder Jetting and Laser...