At Asgaard Metals, we are sustainably producing high-end metal and metal powder from scrap metal. We are rethinking how sustainable metals and powders are made through our patent-pending Spray Forming Process, which is exclusively powered by green and sustainable energy.

Thanks to our closed-loop circular approach, we achieve a material efficiency close to 100%, thereby preserving precious alloying elements in the global value chain.

Unlike typical high-end steel making, our one-step process enables the single melting of scrap into high-quality metal with unrivaled energy efficiency. At the same time, our Spray Formed metal shows superior properties when compared to cast and remelted metal.

Therefore, we can guarantee to return your scrap metal in 1:1 volume with the same or higher quality than what was provided.

High-End Quality

Circularity

Resilient Supply

Tool Steel

Our high-end recycle tool steel

Metal Powder

Cutting edge metal powder for Additive Manufactoring

Our Story

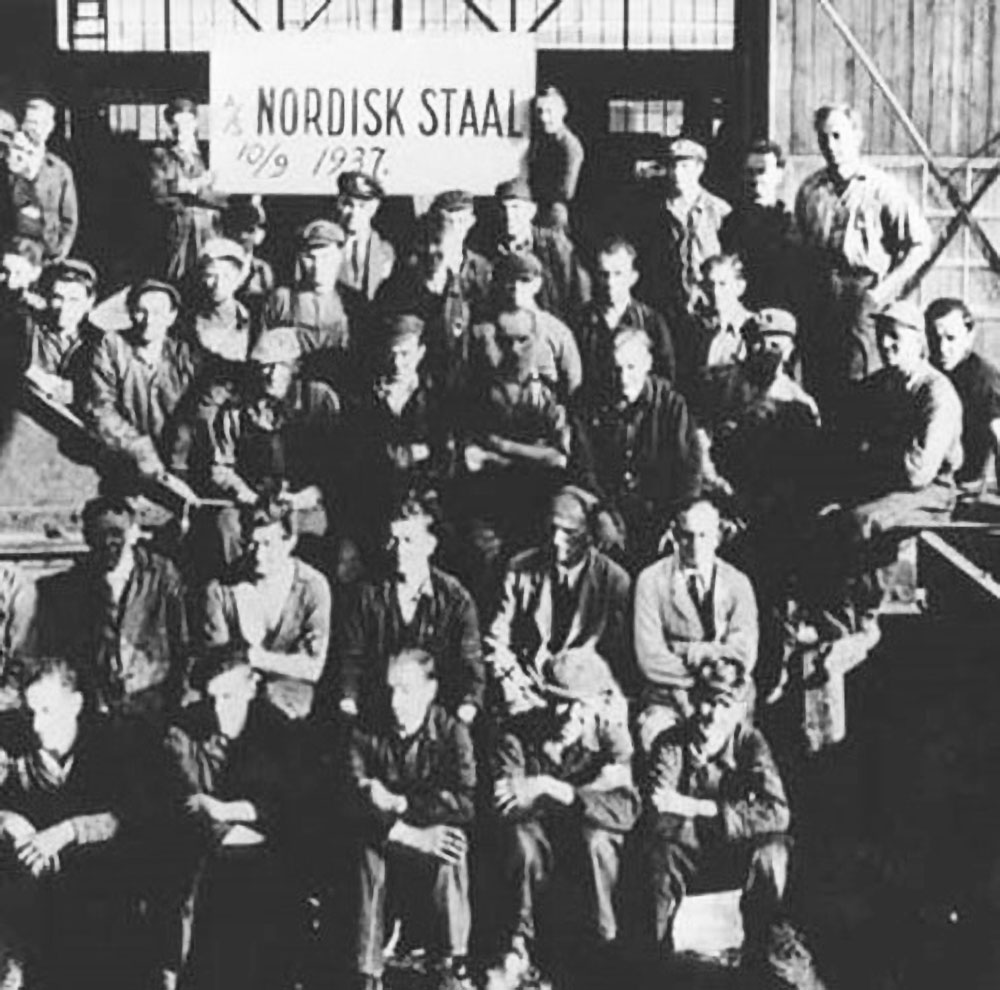

Our story started back in 1932 with Nordisk Staal, a traditional blacksmithing company in Denmark. Way before that, our local area was home to hunters, Vikings, and blacksmiths. Later it became Frederiksværk, our hometown, which was based on handcraft – and forging metals from the Earth. With our Nordic heritage, our craftsmanship, our tech-engineering for the future, and the magic of metal, we feel a belonging to the old Sagas – at least story-wise, and hence our products are named ODIN and THOR, our place is called Asgaard and we, the people, call ourselves Asgardians. All with a glimpse in the eye, of course.

Based on our heritage, Asgaard Metals was a spin-off from Nordisk Staal and was founded in 2021, merging the forging of metals with high-tech engineering. We have developed and patented a revolutionary production process – an entirely new approach for creating recycled spray-formed tool steel and metal powder for 3D printing. A new method with radical impact.

Our Offering

Due to our patent-pending Spray Forming process, Asgaard Metals can make a 100% closed-loop production – a circular process. As a result, we can supply a combination of traditional ultra-high-quality tool steel and novel metal powders for Additive Manufacturing. With our process you can return excess steel, used parts, tools, and other used metals, and Asgaard Metals will then convert it into recycled metal powder and graded steel and metal. As good or better the the original metal. Our process will also secure your supply of tools steels and metals.

Premium quality steel and powders

High-quality steel is essential to ensure the safety, reliability, and performance of engineering systems to ultimately enable the efficiency, productivity, and cost-effectiveness of operations and applications.

Spray-formed steel is superior to conventional cast steel and electro-slag remelted steel. Like powder metallurgical steel, spray-formed steel is characterized by a fine-grained and homogenous microstructure without segregation, making it a steel product of premium quality.

At the same time, the powder produced in the Spray Forming process exhibits superior properties to gas-atomized powders. Our spray-formed powders show excellent sphericity, flowability, and high density. In a research project with the Technical University of Denmark, our powders have been successfully qualified for 3D metal printing (Additive Manufacturing).

Since both, the steel billet and the metal powder are simultaneously created in the same production process, both materials are chemically identical. This enables superb compatibility of the spray-formed steel billet and powder, e.g., for applications such as hybrid additive manufacturing (machined steel + powder), laser cladding (part to be repaired + powder), or powder metallurgical applications (welded shell + powder).

Supply chain resilience

Supply chain resilience is crucial for alloyed steel because it ensures that the necessary raw materials and components are available consistently and reliably, despite unexpected disruptions such as global crises and highly fluctuating prices. This helps to maintain the quality, consistency, and timely delivery of alloyed steel products, which are essential for many industries, including automotive, aerospace, construction, and manufacturing.

Our closed-loop circular manufacturing makes your supply chain more resilient. The valuable alloying elements of your end-of-life tools or products are kept in the steel – without being blended, unnecessarily diluted, and remelted as currently practiced in the industry. Without additional scrap distributors in the supply chain, extra costs, lead times, and the risk of potential trade secrets breaches are minimized.

Through our delivery system, we ensure a secure and resilient supply chain ranging from handling our client’s IP and using patented tools to delivery of your future resources. Instead of worrying about a lack of supplies and long delivery time, you can be secure to receive at least the same amount of metal as what you have provided to Asgaard Metals.

Sustainability

The world we live in isn’t the one we want: we’re facing a drastic climate and ecological crisis that needs transformative solutions. This is the time for radical impact. We engineered a revolutionary and patent-pending new method of design and production to remove the cost barrier and enhance the quality of recycled materials. For a circular, clean, and equitable future, we need true sustainability that’s accountable and transparent.

How our Circular Model works

Based on our recycling model, we can guarantee all the steel you send to us will be reused. Our recycling of your used metal means a better environment, improved strengths, and longevity in the material, and saving costs in scrap material for our clients.

Step 1: Scrap collection. Based on the composition and volume of your material, we pool you into one of our Recycle Communities.

Step 2: Spray forming. We directly transform your scrap into premium powders and solid steel. By disrupting conventional routes, we preserve valuable alloying elements, eliminate the use of primary resources and avoid unnecessary remelting.

Step 3: One-to-one delivery. Get your materials back in a certified ready-to-use condition. After the end of life, we are glad to repeat the process.

Circular

We make materials designed to last longer – that can be reused and recycled again and again.

Upgradable. Upgrading the quality in the process means our material last longer.

Duality. Engineering a dual-based spray-forming system creates an atom structure that ensures components are compatible and can be machined and printed together without problems.

Zero waste to landfill. Using only what we need in our factories, with production offcuts recycled into new high-end steel.

Clean

We want to lower carbon emissions and recycle scrap metal in our cities and productions.

Low impact. Measuring and minimizing environmental impact in our processes.

Using 100% green energy. We only use electricity to operate the oven, and all electricity is made from green renewable energy sources like wind and solar power.

Minimizing the environmental footprint by using the superior resource efficiency of Spray Forming, establishing closed-loop circular economies.

Local

We strive to empower communities and local companies, so everyone benefits from our recyclable model.

Accessible. Designing for the diversity of use makes our products more inclusive.

Local supply chains. We aim to provide work for local talent and economic uplift for communities through local micro-factories reducing transportation of scrap metal.

Transparency. Implementing industry-leading supply chain traceability and code of conduct.

Products

Asgaard Metals produces ultra-high-quality tool steel using unique spraying forming technically. Our steel is 98-100% made from scrap steel, sometimes we add 1-2% virgin material such as chrome, and we use 100% renewable energy sources for our production.

ODIN44

ODIN44Tool SteelOur spray-formed tool steel is available as rounds, bars, flat steel, sheets or precision machined in custom dimensions according to your needs. Spray FormingDue to our patent-pending Spray Forming process, our steel exhibits premium qualities:...

THOR15

THOR15Metal PowdersOur metal powders are gas-atomized through our patent-pending Spray Forming process. The powders are sieved to custom sizes and have been qualified for Additive Manufacturing processes including Laser Powder Bed Fusion, Binder Jetting and Laser...

THOR44

THOR44Metal PowdersOur metal powders are gas-atomized through our patent-pending Spray Forming process. The powders are sieved to custom sizes and have been qualified for Additive Manufacturing processes including Laser Powder Bed Fusion, Binder Jetting and Laser...

Contact

We are a Danish re-cycling metal company, producing high-end tool steel and metal powder for 3D Printing. Get in touch!

Office

Asgaard Metals

Asgaard Metals ApS

Industrivej 25

3300 Frederiksværk

Danmark

Get Directions (Google Map)

Telephone: +45 4035 1048

E-mail: nap@asgaardmetals.com

Regarding career opportunities,

please contact:

career@asgaardmetals.com

Press inquiries, please contact press@asgaardmetals.com

Technical Inquiries

Thomas Dahmen, Ph.D.

Head of Technology

E-mail: tdah@asgaardmetals.com

Phone: +45 5365 2888